Wunderlabel has a wide range of labels which means that you can find the perfect product for your needs. We often get questions from our customers about how to place the tags, how to attach them and which label is best for their item. That is why we have decided to create a tutorial about how to apply labels, complete with concrete examples. We will show you different ways of attaching your labels. With our tips your labels will stick like glue!

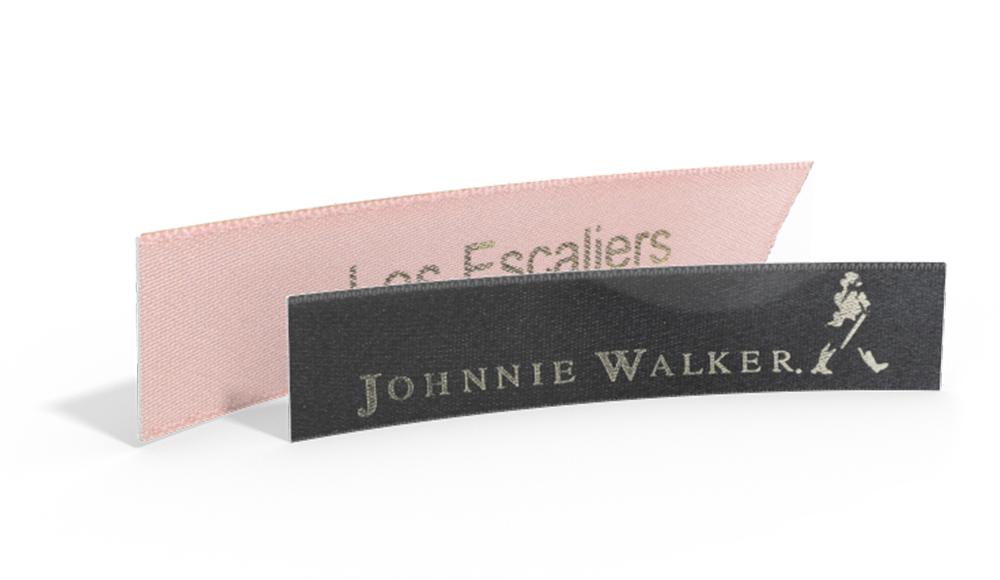

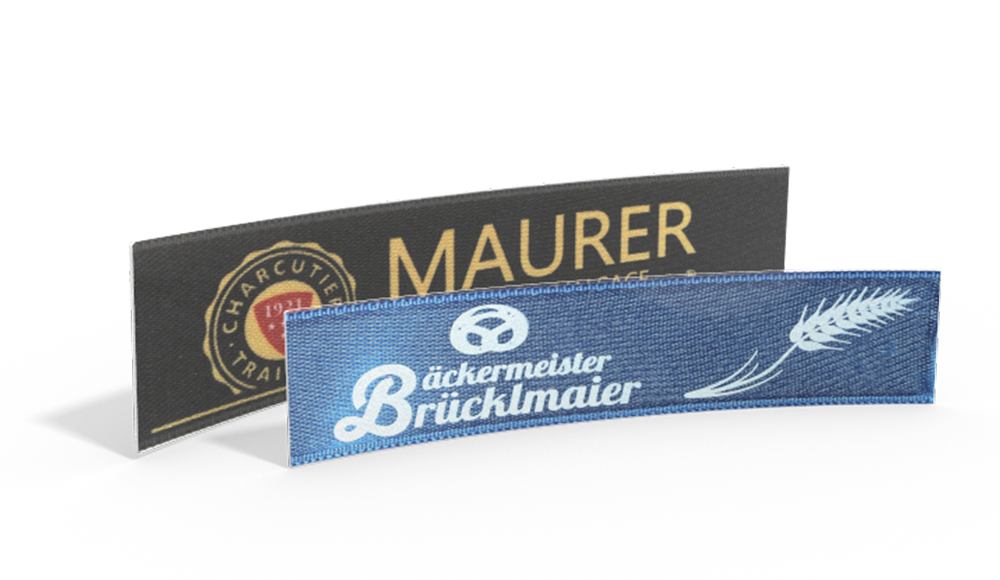

You can find the different folded label options that Wunderlabel offers in the online design tool for Personalized Labels with your Logo under “Label Type”: